{Complying with critical prerequisites of ultracold deployments entails professional valve development. Our cryogenic 3-way globular assembly alternatives are manufactured to provide reliable work even at frostbitten temperatures, typically below -150°C. These mechanisms offer exceptional conveyance regulation in refined materials such as nitrogen, oxygen, and argon, frequently used in markets like LNG, academic equipment, and biomedical facilities. Our experts concentrate on hardy construction, including low-friction locking materials and meticulous forming, to guarantee impermeable functionality. Explore the strengths of refining your cryogenic system with our innovative 3-way orbital assembly products.

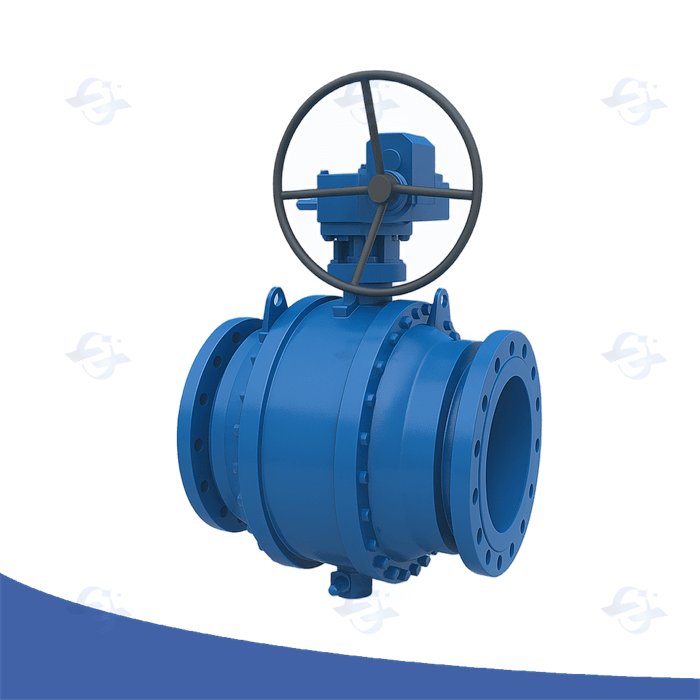

High-Performance Double Block and Bleed Orbital Valve Sets

For demanding systems, particularly where escaping is forbidden, top-tier double block and bleed sphere valves offer unequalled defense. This exclusive design incorporates two autonomous gate valve seals, supplementarily a bleed outlet, allowing for ascertainment of the full shut-off and finding of any conceivable drip. Commonly employed in fuel production, processing transformation, and sub-zero settings, these fixtures remarkably raise operational dependability and cut the hazard of sustained consequence.

Three-Way Chilling Circular Mechanism Formation

Our construction of three-port chilling circular device presents a singular engineering problem. These taps are generally employed in central industrial applications where severe coldness must be upheld. Key matters include matter selection, especially regarding frailty at minor chills, and the demand for close closure to inhibit draining of glacial materials. Elaborate analysis methods and rigorous building steps are needed to ensure stable effectiveness and lifespan under such severe running circumstances.

Arctic Switch Performance in Engineering Applications

These demanding conditions of chilly applications, such as cryogenic natural fuel handling and liquid nitrogen storage, necessitate unfailing shutoff designs. Integral block release devices provide a particularly robust and effective strategy to achieving zero-leak isolation while facilitating periodic maintenance. Their design encompasses a primary shutoff with a small opening passage, allowing monitored pressure expulsion during termination and resumption. This inherent aspect minimizes lingering item entrapment, thereby ensuring outstanding well-being and optimality even under the most severe running cases. Furthermore, the ability to detect escape transit provides valuable testing statistics for function maximization.

Achieving 3-Way Globe Valve Securing in Challenging High-Pressure Cases

Gaining dependable tightness performance with 3-way sphere valves becomes particularly essential when operating within excessive pressure applications. The design must account for significant weights and potential discharge pathways. Specialized components, often including leading-edge metals like corrosion-resistant steel or exotic alloys, are mandatory to survive the unforgiving conditions. Furthermore, elaborate support geometries and exact formation processes are essential to minimize bending and guarantee a watertight attachment even under fluctuating burden cycles. Regular assessment and periodic preservation programs are too vital for lastingness and continued operational stability.

Glacial Ball Valve Leakage Prevention Strategies

Suppressing "leakage" from cryogenic "cryo valves" demands a multifaceted "method". Initial "drafting" considerations are paramount; material "option" must account for extreme "cold levels" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "constituent", meticulous "fabrication" processes – including stringent weld "inspections" and non-destructive "testing" – are vital to ensure structural integrity and eliminate voids that could become "escape routes". A "critical" component is proper "installation"; thermal "contraction" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "overhaul" – including periodic "supervision" for signs of wear and "patching" of any identified issues – is indispensable for maintaining a reliable, leak-tight "lock”. Ultimately, a robust "system" incorporating these elements is necessary to ensure the safe and efficient "function" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "shortfall", safety "menaces", and costly "halt”.

Dual Clamp and Drain Mechanism Check Protocols

To certify the integrity and safety of critical piping grids, rigorous parallel block and drain valve evaluation methods are essential. These tests, often mandated by regulatory bodies and industry best methods, typically involve simulating simultaneous closure of two isolation valves while simultaneously ensuring the drain system remains functional and correctly discharges any trapped fluid. A common technique is to utilize a pressure examination where the system is pressurized to its maximum working pressure, and the drip rate around the closed valves is meticulously documented. The drain apparatus's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of analysis results, including any irregularities observed, is paramount for maintaining a reliable performance.

Apprehending Overall Block Drain Component Capability

With the aim to successfully oversee load structures, a detailed understanding of integral block emission apparatus capability is completely essential. These tailored devices mostly respond to properly discharge unwanted strain from a network during appointed active sections. A usual placement comprises a closed compartment connected to the leading compression source, granting an restricted discharge upon required. The natural configuration reduces the threat of surpass of threshold pressure, preserving both the devices and the local zone. Regular inspection and upkeep are essential to secure top productivity.

Deciding on the Fitting 3-Way Ball Valve for Cryogenic Fluids

Electing a right 3-tri-ball apparatus for cryogenic functions demands careful analysis of several critical features. The extremely low cold levels inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present atypical challenges. Material determination is paramount; only materials with proven agreement and ductility at these temperatures, such as alloyed steel grades like 304L or 316L, or specialized metallic alloys, should be scrutinized. Furthermore, the apparatus's sealing capacity is vital to prevent escapements, requiring advanced stem sealing templates and low-temperature agents. Finally, pressure values and actuation strategies, taking into account potential pressure jumps, must be thoroughly matched to the system's stipulations. Neglecting these considerations can lead to catastrophic failure and safety menaces.

Freezing Rotary Valve Composition Agreement Reference

Identifying the appropriate composition for cryogenic ball valves is paramount, given the harsh temperatures involved. This compendium highlights common compositions and their reaction when exposed to cryogenic fluids such as solution nitrogen, fluid helium, and oxygen. Stainless steels, particularly classes 304 and 316, often demonstrate adequate sturdiness and corrosion resistance, though martensitic metals require careful consideration regarding brittleness. Aluminum alloys can be suitable for certain applications, however, their workability and shielding to specific chemicals needs complete evaluation. Copper alloys, while offering some merits, may exhibit lowered efficacy at these minimal temperatures. Consultation with producers and comprehensive testing is essential to verify stability and welfare in cryogenic tasks.

Optimizing Double Shutoff and Vent Setup Efficiency

Accomplishing optimal capability in double shutoff and vent configurations hinges on a multifaceted approach. Careful scrutiny of part selection is crucial, with a focus on ingredient suitability and impact evaluation. Regular supervision of drain avenues for congestion is indispensable, often demanding the use of exclusive testing apparatus. Furthermore, practice tuning—including analysis of transport rates and force gap—can noticeably improve overall setup firmness and reliability. Finally, adherence to producer directives and the carrying out of a detailed preservation routine are indispensable for long-term trustworthiness and durability.

Double Block And Bleed Valve

Double Block And Bleed Valve